Bolt Hecsagon Dur Carbon Din 933

| Enw cynhyrchion | Bollt Hecsagon Dur Carbon DIN 933/ISO4017 |

| Safonol | DIN, ASTM / ANSI JIS EN ISO, AS, GB |

| Gradd | Gradd Dur: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Gorffen | Sinc (Melyn, Gwyn, Glas, Du), Galfanedig Dip Hop (HDG), Ocsid Du, Geomet, Dacroment, anodization, platiau nicel, platiau sinc-nicel |

| Proses Gynhyrchu | M2-M24: Ffrwgio Oer, Ffrwgio Poeth M24-M100, Peiriannu a CNC ar gyfer clymwr wedi'i addasu |

| Cynhyrchion wedi'u Haddasu Amser Arweiniol | 30-60 diwrnod, |

| Samplau am ddim ar gyfer clymwr safonol | |

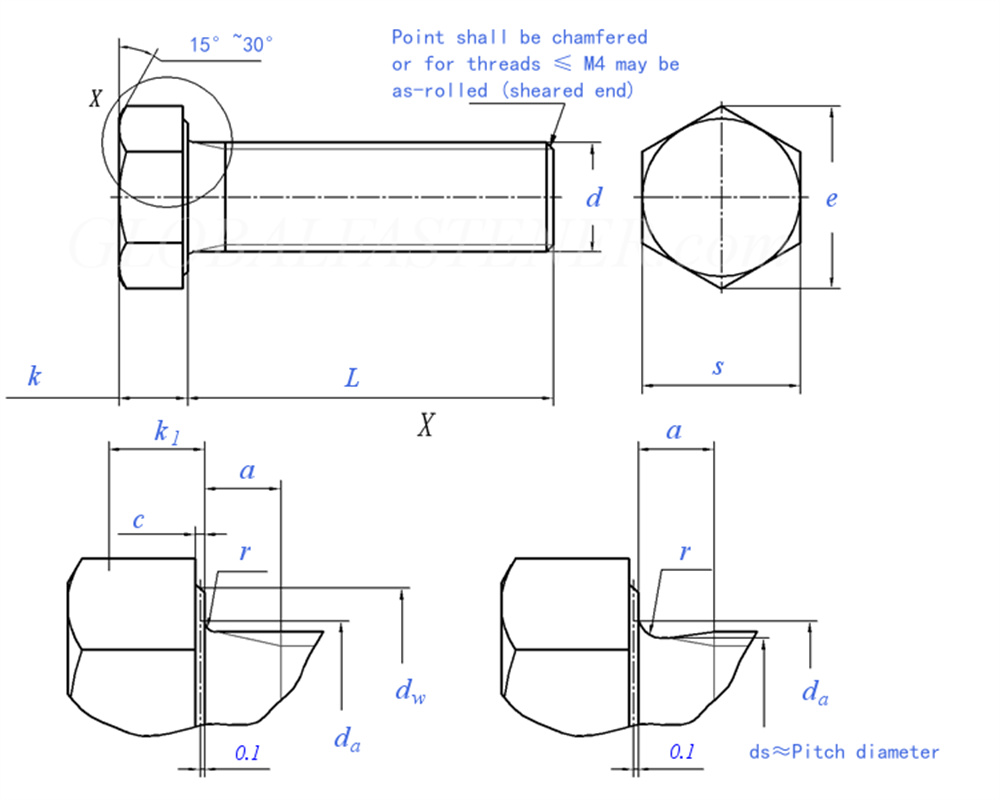

| Edau Sgriw | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Traw | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| a | uchafswm | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 4 | 4.5 | 5.3 | |

| munud | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | ||

| c | uchafswm | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| munud | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | uchafswm | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| dw | Gradd A | munud | 2.27 | 3.07 | 4.07 | 4.57 | 5.07 | 5.88 | 6.88 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Gradd B | munud | 2.3 | 2.95 | 3.95 | 4.45 | 4.95 | 5.74 | 6.74 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Gradd A | munud | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Gradd B | munud | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| k | Maint Enwol | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Gradd A | uchafswm | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| munud | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Gradd B | uchafswm | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| munud | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Gradd A | munud | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Gradd B | munud | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | munud | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | maint enwol = uchafswm | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Gradd A | munud | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Gradd B | munud | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Edau Sgriw | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Traw | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| a | uchafswm | 6 | 6 | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | |

| munud | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | ||

| c | uchafswm | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| munud | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | uchafswm | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| dw | Gradd A | munud | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Gradd B | munud | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Gradd A | munud | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Gradd B | munud | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| k | Maint Enwol | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Gradd A | uchafswm | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| munud | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Gradd B | uchafswm | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| munud | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Gradd A | munud | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Gradd B | munud | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | munud | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | maint enwol = uchafswm | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Gradd A | munud | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Gradd B | munud | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Edau Sgriw | (M45) | M48 | (M52) | M56 | (M60) | M64 | ||||||||

| P | Traw | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | |||||||

| a | uchafswm | 13.5 | 15 | 15 | 16.5 | 16.5 | 18 | |||||||

| munud | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | ||||||||

| c | uchafswm | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

| munud | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||||||||

| da | uchafswm | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 | |||||||

| dw | Gradd A | munud | - | - | - | - | - | - | ||||||

| Gradd B | munud | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 | |||||||

| e | Gradd A | munud | - | - | - | - | - | - | ||||||

| Gradd B | munud | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |||||||

| k | Maint Enwol | 28 | 30 | 33 | 35 | 38 | 40 | |||||||

| Gradd A | uchafswm | - | - | - | - | - | - | |||||||

| munud | - | - | - | - | - | - | ||||||||

| Gradd B | uchafswm | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 | |||||||

| munud | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | ||||||||

| k1 | Gradd A | munud | - | - | - | - | - | - | ||||||

| Gradd B | munud | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 | |||||||

| r | munud | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 | |||||||

| s | maint enwol = uchafswm | 70 | 75 | 80 | 85 | 90 | 95 | |||||||

| Gradd A | munud | - | - | - | - | - | - | |||||||

| Gradd B | munud | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |||||||

Nodweddion a Manteision

Bollt Hecsagon Dur Carbon Din 933: Yr Ateb i'ch Anghenion Clymu

O ran clymu, rydych chi eisiau ateb sy'n gadarn, yn ddibynadwy ac yn hawdd i'w osod. Mae Bollt Hecsagon Dur Carbon Din 933 yn ticio'r holl flychau cywir trwy gynnig bollt gwydn ac amlbwrpas y gellir ei ddefnyddio ar draws ystod eang o gymwysiadau.

Wedi'i wneud o ddur carbon o ansawdd uchel, mae'r bollt hwn wedi'i gynllunio i wrthsefyll amgylcheddau caled, straen uchel a llwythi trwm. Mae'r pen hecsagonol yn darparu ffit diogel a thynn, tra bod yr edau yn caniatáu ar gyfer gosod a thynnu hawdd.

Gan fesur rhwng 6mm a 100mm o hyd, mae'r bollt hwn ar gael mewn amrywiaeth o feintiau i gyd-fynd â gwahanol brosiectau a gofynion. P'un a ydych chi'n adeiladu peiriant, yn codi strwythur neu'n clymu offer at ei gilydd, mae'r bollt hwn yn cynnig y cryfder a'r gwydnwch sydd eu hangen arnoch i wneud y gwaith.

Ar ben hynny, mae Bollt Hecsagon Dur Carbon Din 933 yn hawdd i'w gynnal ac nid yw'n dirywio'n hawdd dros amser. Mae hyn yn golygu y gallwch ddibynnu ar ei effeithiolrwydd am flynyddoedd ar ôl ei osod.

I'r rhai sy'n chwilio am follt sydd yn fforddiadwy ac o ansawdd uchel, mae'r bollt dur carbon hwn yn ddewis perffaith. Nid yn unig y mae'n dileu'r angen am atebion clymu drud a chymhleth, ond mae hefyd yn hawdd ei osod a'i dynnu, gan arbed amser ac ymdrech gwerthfawr i chi.

I grynhoi, mae Bollt Hecsagonol Dur Carbon Din 933 yn ddatrysiad clymu hynod ddibynadwy ac ymarferol y gellir ei ddefnyddio mewn amrywiaeth o gymwysiadau. Fe'i cynlluniwyd ar gyfer y gwydnwch mwyaf a'r rhwyddineb defnydd, gan ei wneud yn ddewis poblogaidd i beirianwyr, adeiladwyr a selogion DIY fel ei gilydd. Ymddiriedwch yn Bollt Hecsagonol Dur Carbon Din 933 i roi datrysiad i chi sy'n ticio'r holl flychau, ni waeth pa brosiect rydych chi'n gweithio arno.