Bollt Hecs Din 931 / iso4014 933 / iso4017 Gradd 4.8

| Enw cynhyrchion | BOLT HEX DIN 931/ISO4014 hanner edau |

| Safonol | DIN, ASTM / ANSI JIS EN ISO, AS, GB |

| Gradd | Gradd Dur: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Gorffen | Sinc (Melyn, Gwyn, Glas, Du), Galfanedig Dip Hop (HDG), Ocsid Du, Geomet, Dacroment, anodization, platiau nicel, platiau sinc-nicel |

| Proses Gynhyrchu | M2-M24: Ffrwgio Oer, Ffrwgio Poeth M24-M100, Peiriannu a CNC ar gyfer clymwr wedi'i addasu |

| Cynhyrchion wedi'u Haddasu Amser Arweiniol | 30-60 diwrnod, |

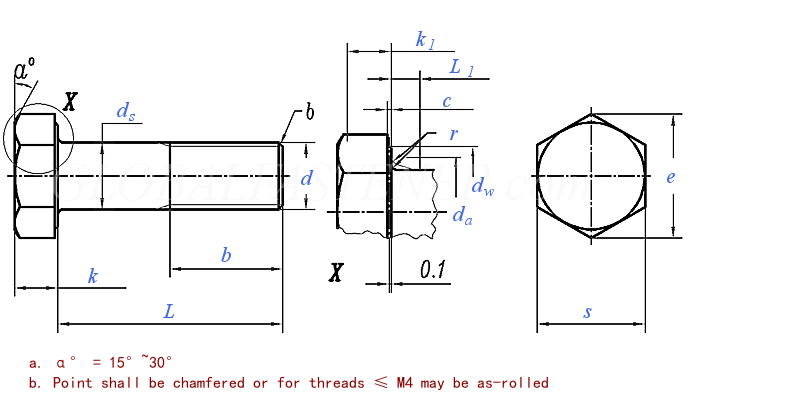

| Edau Sgriw | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Traw | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125 <L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | uchafswm | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| munud | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | uchafswm | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | maint enwol = uchafswm | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| Gradd A | munud | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| Gradd B | munud | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | Gradd A | munud | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Gradd B | munud | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Gradd A | munud | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Gradd B | munud | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | uchafswm | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Maint Enwol | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Gradd A | uchafswm | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| munud | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Gradd B | uchafswm | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| munud | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Gradd A | munud | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Gradd B | munud | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | munud | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | maint enwol = uchafswm | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Gradd A | munud | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Gradd B | munud | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Hyd yr Edau b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Edau Sgriw | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Traw | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125 <L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | uchafswm | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| munud | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | uchafswm | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | maint enwol = uchafswm | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| Gradd A | munud | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| Gradd B | munud | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | Gradd A | munud | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Gradd B | munud | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Gradd A | munud | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Gradd B | munud | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | uchafswm | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Maint Enwol | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Gradd A | uchafswm | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| munud | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Gradd B | uchafswm | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| munud | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Gradd A | munud | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Gradd B | munud | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | munud | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | maint enwol = uchafswm | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Gradd A | munud | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Gradd B | munud | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Hyd yr Edau b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Edau Sgriw | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | Traw | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125 <L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | uchafswm | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| munud | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | uchafswm | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | maint enwol = uchafswm | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| Gradd A | munud | - | - | - | - | - | - |

|

|

|

|

|

| |

| Gradd B | munud | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | Gradd A | munud | - | - | - | - | - | - |

|

|

|

|

|

|

| Gradd B | munud | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | Gradd A | munud | - | - | - | - | - | - |

|

|

|

|

|

|

| Gradd B | munud | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | uchafswm | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Maint Enwol | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| Gradd A | uchafswm | - | - | - | - | - | - |

|

|

|

|

|

| |

| munud | - | - | - | - | - | - |

|

|

|

|

|

| ||

| Gradd B | uchafswm | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| munud | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | Gradd A | munud | - | - | - | - | - | - |

|

|

|

|

|

|

| Gradd B | munud | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | munud | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | maint enwol = uchafswm | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| Gradd A | munud | - | - | - | - | - | - |

|

|

|

|

|

| |

| Gradd B | munud | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Hyd yr Edau b | - | - | - | - | - | - |

|

|

|

|

| |||

Nodweddion a Manteision

Ym myd clymwyr, mae Bollt Hecsagon Din 931, ISO4014 933, ac ISO4017 Gradd 4.8 ymhlith y cynhyrchion mwyaf poblogaidd. Mae'r bolltau hecsagon hyn yn hanfodol mewn adeiladu a gweithgynhyrchu gan eu bod yn cynnig sefydlogrwydd rhagorol, gwydnwch a gallant wrthsefyll pwysau a thensiwn uchel.

Mae'r Bollt Hecs Din 931, ISO4014 933, ac ISO4017 Gradd 4.8 ar gael mewn amrywiaeth o feintiau i gyd-fynd â gwahanol gymwysiadau. Mae'r bolltau hyn wedi'u gwneud o ddur carbon gyda gorffeniad platiog, gan sicrhau ymwrthedd i rwd a chorydiad. Fe'u cynlluniwyd gyda phennau chwe ochr i ddarparu gafael ddiogel ar gyfer offer fel wrench neu gefail. Defnyddir bolltau hecs yn gyffredin ar gyfer clymu dau wrthrych neu fwy gyda'i gilydd, gan eu gwneud yn ddelfrydol ar gyfer amrywiol ddiwydiannau fel modurol, awyrofod, adeiladu ac amaethyddiaeth.

Un o fanteision pwysicaf defnyddio'r bolltau hecsagonol hyn yw eu cryfder a'u gwydnwch. Gall y bolltau hyn wrthsefyll pwysau a thensiwn uchel, gan eu gwneud yn ddelfrydol ar gyfer sicrhau offer a pheiriannau mecanyddol trwm. Yn ogystal, mae caledwch y bolltau yn sicrhau nad ydynt yn agored i anffurfiad nac ystumio pan fyddant yn agored i rym allanol.

Mae'r Bollt Hecs Din 931, ISO4014 933, ac ISO4017 Gradd 4.8 yn cynnig perfformiad uwch mewn amgylcheddau llym. Yn ogystal â'u platio sy'n gwrthsefyll cyrydiad, gallant wrthsefyll amlygiad i wres, oerfel a lleithder. Mae hyn yn bwysig mewn lleoliadau diwydiannol lle gall tymereddau eithafol, cemegau a dŵr achosi niwed i glymwyr ac, yn ei dro, beryglu cyfanrwydd y system gyfan.

Gellir defnyddio'r bolltau hecsagonol mewn gwahanol ffurfiau yn dibynnu ar y diwydiant neu'r gofynion penodol. Mae rhai yn eu defnyddio gyda golchwyr a chnau ar gyfer diogelwch ychwanegol tra bod eraill yn eu defnyddio gydag angorau neu blygiau sgriw i sicrhau gwrthrychau i waliau a nenfydau. Waeth sut maen nhw'n cael eu defnyddio, mae'r Bolt Hecsagonol Din 931, ISO4014 933, ac ISO4017 Gradd 4.8 yn chwarae rhan hanfodol wrth gadw gwahanol systemau a phrosiectau gyda'i gilydd.

I gloi, mae bolltau hecsagonol yn hanfodol mewn amrywiol ddiwydiannau yn fyd-eang, ac maent yn parhau i gynnig perfformiad a dibynadwyedd eithriadol. Nid yw'r Bolt Hecsagonol Din 931, ISO4014 933, ac ISO4017 Gradd 4.8 yn eithriad, ac maent yn darparu gwerth rhagorol am arian. Y bolltau hyn yw asgwrn cefn llawer o systemau, ac ni ellir tanamcangyfrif eu pwysigrwydd.